Manufacturer, Supplier of Vacuum Calibration Machine

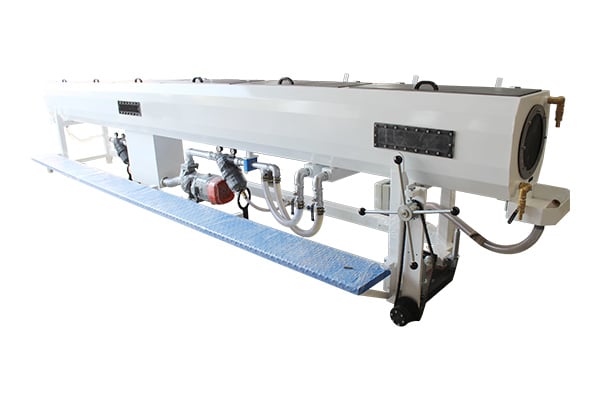

Our downstream equipment has set a strong niche in the market, and influenced the market through delivering unmatched quality experience, among vacuum calibration machine is one that is designed with the utmost prudence for measuring the pipes made of the different type of polymer. This vacuum calibration machine is available with controllable vacuum (dry sizing) or cooling water (wet sizing) as per the end user needs. With respect to the operation area, the machine is made of the high quality stainless steel material having excellent corrosion resistance and hence promises for outlasting.

The unit is mounted on the stainless steel rails and is feasible to move and synchronize with extrusion line as per the requirement. The offered vacuum calibration unit is constructed under the stern caution of the quality analyst team in order to ensure its conformity with the set quality parameters and procure nonpareil gamut that can outperform excellently across lifetimes. Owing the miscellaneous requirements of the pipe making industries, this vacuum calibration machine is made available in the different length ranging from 16 mm to 630 mm and cooling length ranging from 4000 mm to 8000 mm. Further, we are well versed to maximize the cooling efficiency of the respected vacuum calibration unit as upon customer request.

| MODEL | Unit | VST 110 | VST 200 | VST 250 | VST 315 | VST 450 | VST 630 |

| Pipe Range | mm | 16 – 110 | 20 – 200 | 25-250 | 50-315 | 75-450 | 110-630 |

| Cooling Length | mm | 4000/6000 | 6000 | 6000 | 6000/8000 | 6000/8000 | 6000/8000 |

Convincing Benefits of Vacuum Calibration Machine:

- The use of high quality S.S material ensures highest corrosion resistance

- No water degradation is guaranteed

- Simple design and the bayonet spray nozzle help easy cleaning

- Equipped Toggle clamp entitles opening and closing of the door

- The pressure gauge helps determine blockage of the filter

- Temperature sensor, level indicator is provided with angle seat valve

- The reverse and forward of the tank can be accomplished manually

- Up & down tank movement can be accomplished by screw jack

- PLC control system helps control all the equipment automatically